NAME OF CUSTOMER : M/S HONDA CARS INDIA LIMITED, TAPUKARA, ALWAR RAJASTHAN

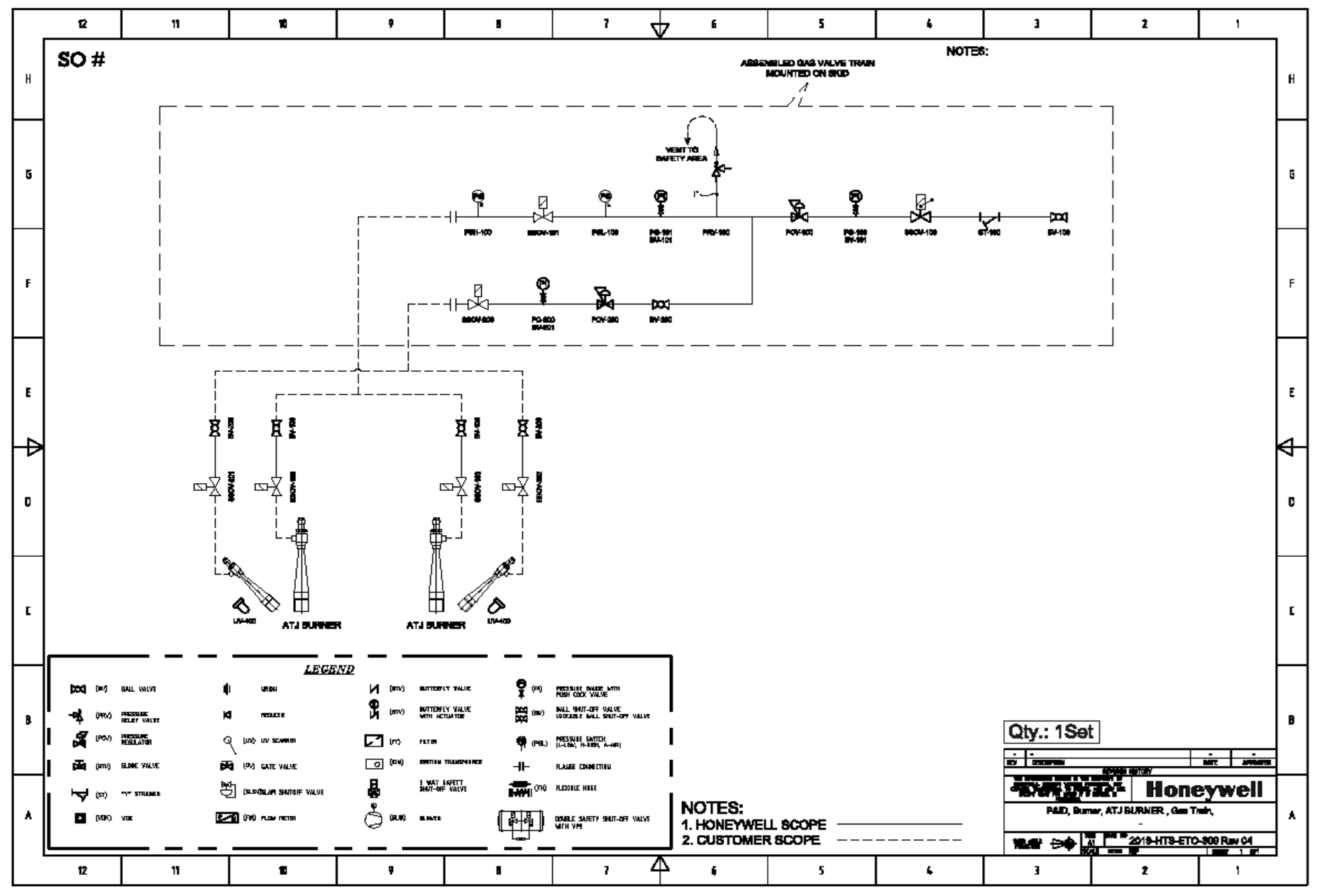

SUBJECT : PT CASTING, POT ROOM MODIFICATION

FACTORS LEADS US TO WIN

- HONDA - Was looking for complete manual to reputed branded automation solution with all the safety requirement and wanted a single source for all kind of work.

- WORK SCOPE - complete SITC (supply, installation testing commissioning)

- CHALLENGE - to dismantle all the previous setup and place the new gas train, panel and burner in 2 shift i.e. 16 hours

WINING PREPOSITION

- HONEYWELL - A well known reputed brand name with all kind of offerings to automat any kind of application.

- MANTECH - Already registered vendor, PTR of Honda plant conversion of 56 burners from LPG to CNG.

- So the combination of Honeywell offerings and Channel Partner with capabilities to provide turnkey solution as per Honeywell expectation lead us to win the case.

CASE HISTORY

- Honda Siel first approached Taikisha for conversion early 2011.

- Taikisha submitted the quotation for dual header gas trains which was a heavy investment for Honda Siel as it needs to change many things like existing gas trains, addition of extra header in plant etc.

- Due to low market demand, the plant was not running to full capacity, so they decided to go for conversion in existing trains which was a low cost option.

- They approached Mantech for the proposal but Taikisha being a Maxon OEM we regretted the quotation initially.

- Honda approached Weishaupt for competitive quote and almost finalized to award the contract.

PT-CASTING PREVIOUS CONDITION –POT ROOM SPC

- PRESENT CONDITION : - Manual burner are being used for pot pre heating.

- REQUIREMENT : - Required automatic burner system.

- PURPOSE : - To enhance the safety and to prevent fire explosion.

SITE INSTALLATION PHOTOGRAPHS

Join us for a Safer

More Secure Industrial Future.