MAXON

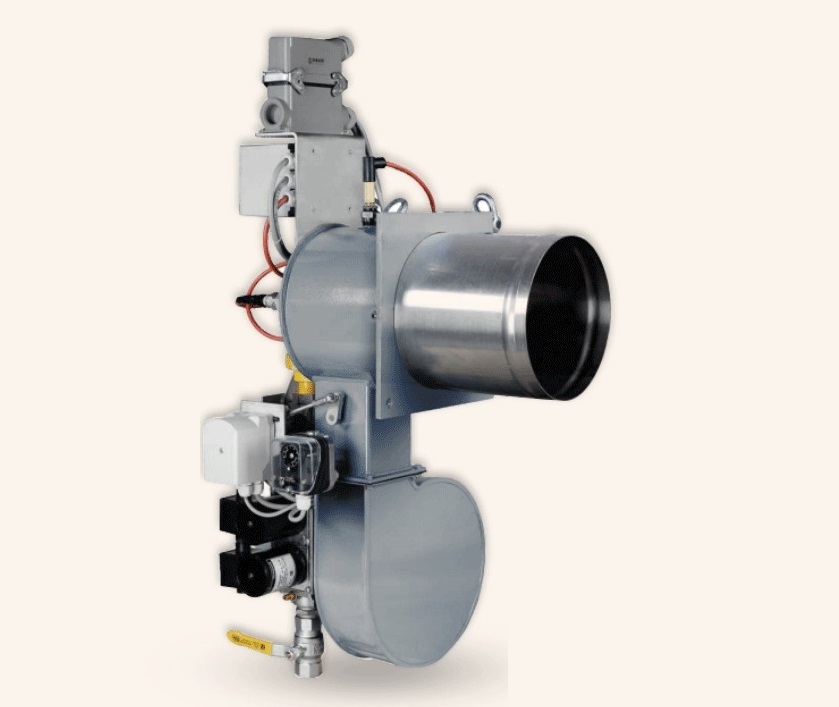

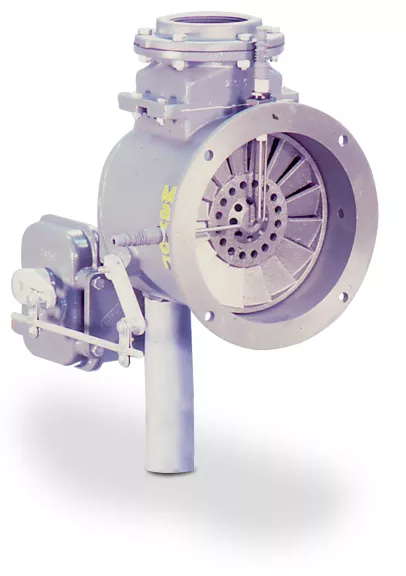

OVENPAK

OVENPAK Burners are nozzle-mixing gas burners for many industrial direct-fired applications

Burns any clean fuel gas

Fires into passing air streams

Requires only low pressure gas

Provides clean combustion with low NOx levels

Compact burner design provides quick and easy installation

Simple field adjustment and maintenance

Gas Burners provide outstanding performance in ovens and dryers, paint finishing lines, paper and textile machines, food baking ovens, coffee roasters, grain dryers, and fume incinerators.

OVENPAK® LE

Burns any clean fuel gas

Operates on low gas supply pressures

Provides clean combustion with low NOx and CO levels

Compact burner design provides quick and easy installation

Balanced pressure design for easy commissioning and adjustment

Visible ignition action speeds commissioning and maintenance

High turndown for exceptional process control

Unopack-300

9KW Min to 325KW Max Capacity

Up to 36:1 Thermal Turndown

Gas Flow: 0.9Nm /hr to 33Nm /hr

Works with NG, LPG, or Propane

Precise Temperature Control

Inlet Pressure: 18-22mbar

Flame Length: 1000mm

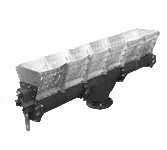

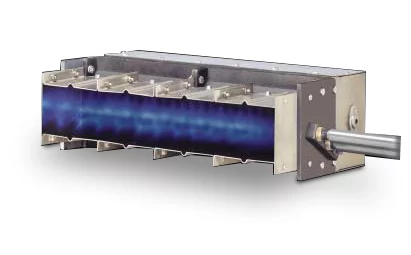

Duct Fire Burner LV AIRFLO

Series LV AIRFLO® burners provide stable, efficient, raw gas operations in air streams with relatively low duct velocities

Duct static pressure drops may be as low as 0.2” wc

Produces clean and odor-free combustion with natural or propane gases

Air stream temperatures upstream of a Series LV AIRFLO® burner can be up to 1050°F

Low air stream oxygen levels can be tolerated without a need to add primary combustion air to the system

Modular burner design provides burner assembly configurations and total heat release for maximum application flexibility

17 varieties of Series LV AIRFLO® burners available, each optimized in materials and/or performance factors to match your specific application requirements

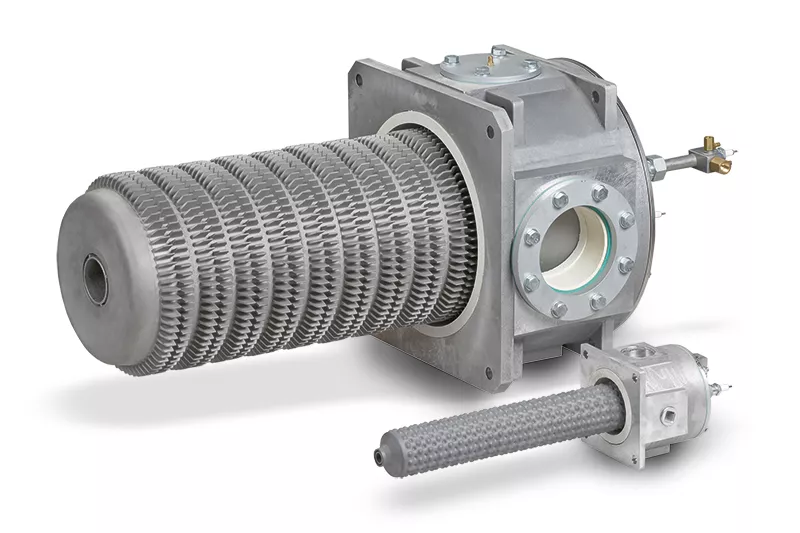

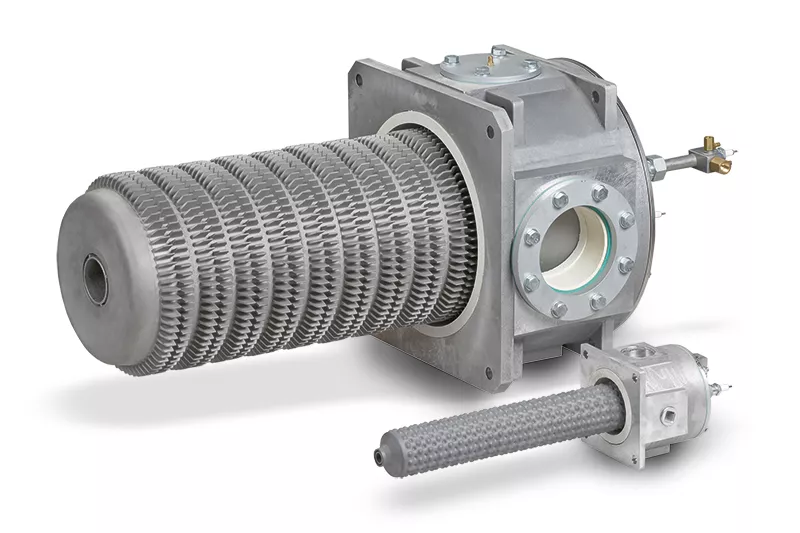

Linear Array Burner COMBUSTIFUME

For direct-fired fume incineration and higher temperature process air heating applications

Modular burner design provides burner assembly configurations and total heat release for maximum application flexibility

COMBUSTIFUME® Burner provides stable, efficient, raw gas operations in air streams with oxygen levels as low as 16% (by volume), or with inlet temperatures up to 1050°F (566°C)

Burns clean and odor-free with low levels of NOx production

When air stream oxygen content is low, primary combustion air may be added through the COMBUSTIFUME® Burner system to produce combustion of most clean gaseous fuels

Fume incineration costs are minimized by direct firing COMBUSTIFUME® Burner in the effluent air stream

12 different varieties of COMBUSTIFUME® Line Burners available, each optimized in materials and/or performance factors to match your specific application requirements

M-PAKT

Produces extremely low emissions of NOx and CO

Burns natural gas or propane

Flame contained almost entirely inside the discharge sleeve

Compact packaged design with a variety of control methods

Durable steel outer construction with stainless steel internals

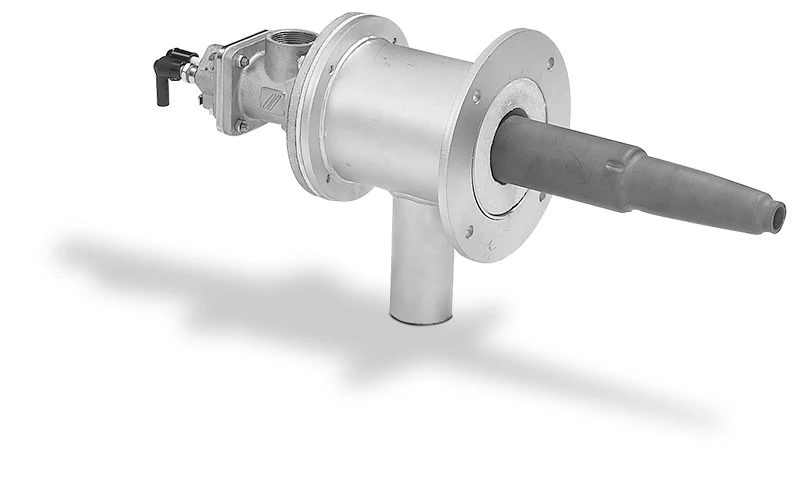

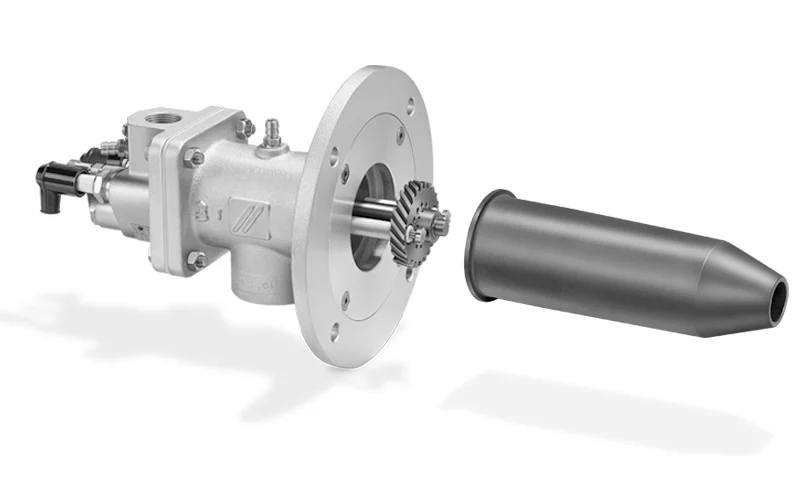

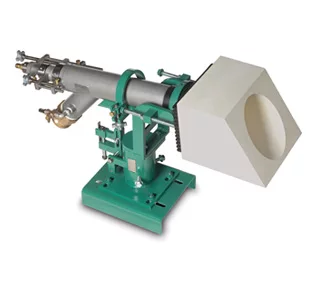

Tube-O-Flame

Nozzle-mixing, refractory-less burners for tube firing

Burns any clean, low pressure fuel gas

Increases heat transfer efficiencies with long, swirling flame pattern

Promotes faster bring-up times with 20:1 turndown capabilities

Easy installation due to flange-mounted compact design

Simple start-up and field adjustments

Low horsepower requirements reduce initial and operating costs

Produces low levels of NOx in combustion products

Generates less noise than open-port tube firing

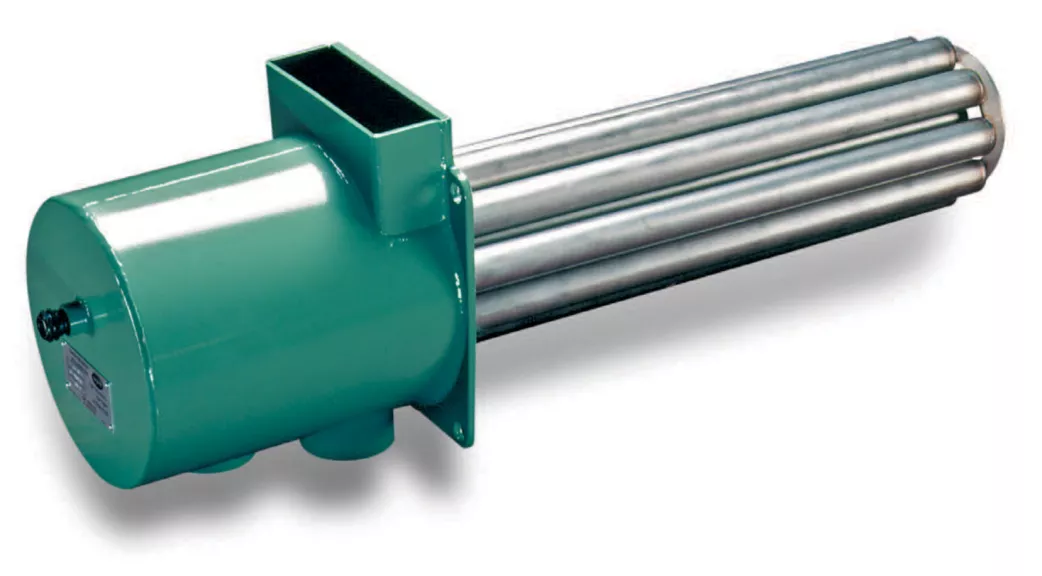

Tube-O-Therm

Fires directly into small-bore immersion tubes

Burner-to-tube direct firing system allows uniform heat transfer, eliminates “hot spots”, and produces faster bring-up times

Economical and efficient package design with integral low power blower costs less and saves energy (external blower models also available)

No hassle installation and easy maintenance access with wall mounted design

Burns natural, propane or butane gas and produces reduced levels of NOx and CO

Flame scanner capability for all sizes

Four models sized for 3”, 4”, 6”, 8” and 10” diameter tubes

Heat releases up to 8,500,000 Btu/hr

No powered exhaust required, saving energy

KINEDIZER LE

Field proven low emissions. State-of-the-art low NOx firing - adjustable for application flexibility

Lower NOx and less excess air than standard KINEDIZER® burners

Rugged design for oxidizers, process heaters, kilns, furnaces, dryers, waste incineration and other high temperature applications

Available in a wide range of capacities, each with turndown as high as 20:1

Burns natural gas, propane or other fuel gases

Provides excellent stirring and mixing with its medium velocity exhaust

Accepts preheated and vitiated combustion air

KINEMax LE

Exit velocities up to 275 ft/s (190 miles/h) to promote workload heat penetration and better furnace temperature uniformity

Operate on-ratio, with excess fuel or with excess air to meet the specific demands of your combustion process needs

Burns most clean, low pressure gaseous fuels or light oil

Turndown capability up to 48:1

Maximum application flexibility with 7 different sizes and maximum capacities ranging from 0.38 MBtu/h up to 8.4 MBtu/h

Lower fuel consumption using preheated combustion air (up to 800 °F)

Refractory block for chamber temperatures up to 3000 °F

Removable backplate, providing access for easy inspection and/or maintenance

KINEMAX® burners can be used with oxygen enriched combustion air

CROSSFIRE

High moisture air streams

Low O2 air streams

Highly inert air streams

Parallel velocities up to 4000 fpm, cross velocities up to 3000 fpm

NOx levels of 25 ppm and CO levels of 250 ppm at 3% O2 are possible

Contact your Maxon sales representative about your specific application

Temperature uniformity to enhance product quality

Up to 25:1 turndown for process flexibility

High firing capacity - up to 2,500,000 Btu/hr/ft (732 kW/ft)

Nozzle-mixing line burner for use with low pressure natural gas firing

Also available in stainless steel housings and nickel-plated body versions

OPTIMA SLS

Extremely Clean, reliable heat with ultra Low NOx and CO production for ease of air permitting and environmental compliance

Large capacity heat releases with a compact, robust flame geometry

Intelligent ratio control for reliable operation and optimal fuel efficiency

Direct factory operational support with optional communication gateway

All steel and high temperature alloy construction for reduced weight and increased durability

Fuel flexible with natural gas, propane, and butane capability. Contact MAXON for other fuels

Configurable for dryers, air heaters, ovens, kilns, process heaters, paper machines, and a variety of other industrial heating equipment

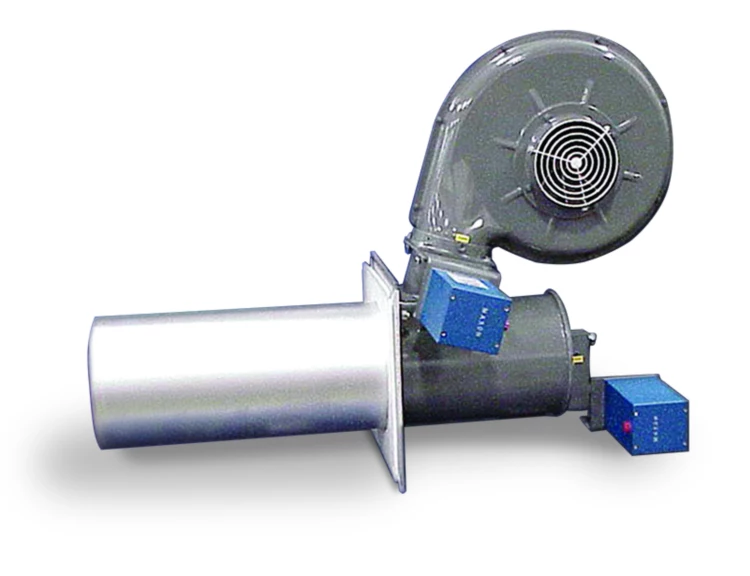

Pilot Burner VALUPAK

High turndown.

Available in 6 sizes

Capacities: 0.007 MBtu/hr - 4 MBtu/hr.

Stable and clean combustion.

Suitable for UV scanner and flame rod.

Natural gas and LPG.

Low gas pressure requirements.

Ease of installation and operation with low maintenance requirements.

All metal construction.

Multi voltage and frequency blower motors.

Kromschroeder

BIO

Burner size: 50 to 200

Capacity: 40 to 1000 kW

Uses: cold air, hot air, flat flame, high-temperature applications

Fuel Type: natural gas, coke oven gas, town gas or liquefied gases as well as biologically produced methane or low calorific value gases upon request

Burner length: 50 to 1000 mm

Gas connection: threaded

Air connection: threaded or flanged (BIOA: tube connection)

Versions Available: burner with integrated ignition lance, housing with internal insulation

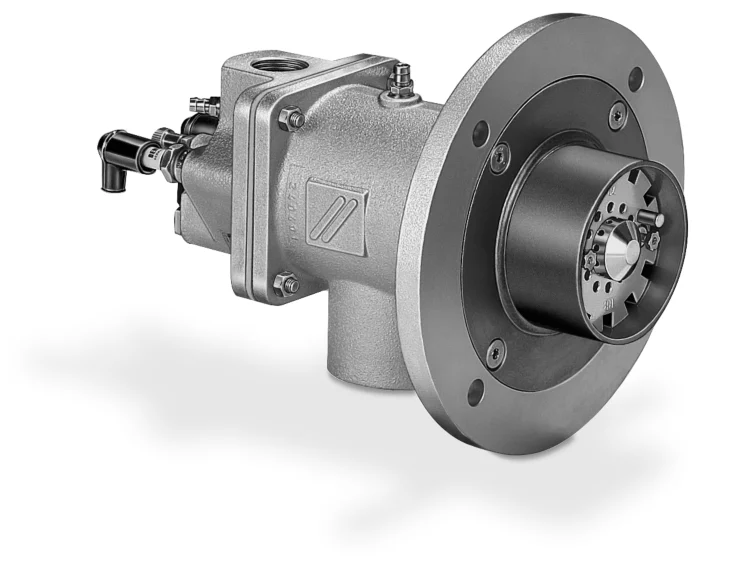

BICR

Self-recuperative furnace burner with a small footprint

Burner size: 65/50 to 100/80

Capacity: 20 to 100 kW

Fuel type: natural gas or liquefied gases

Threaded air and gas connections

ECOMAX

Burners with integrated recuperator for direct or indirect heating of furnace systems

3 versions: with ceramic burled tube recuperator, cast steel ribbed tube recuperator or flat tube recuperator

7 sizes from 25 to 500 kW

Direct ignition and monitoring

Gas type: natural gas, town gas, LPG or LCV gas

Flame velocity: 120 to 150 m/s

Control: ON/OFF

ECOMAX LE

Flame and Flameless modes: switching temperature of 850°C (1560°F)

Up to 7% improved efficiency over standard ECOMAX®

3 burner sizes covering a capacity range of 36 to 100 kW (136 to 378 kBTU/h)

Available with metallic recuperator (..M) or with a ceramic recuperator (..C)

Fits in the same footprint as the current Ecomax® for easy upgrades

Packaged with BCU4 series controls

Fuel type: natural gas, gas supply pressure 80 mbar / 32” w.c.

Air supply pressure 90 mbar / 36” w.c.

Flame velocity: 120 to 150 m/s

Control: ON/OFF or HIGH/LOW pulse

BIC Burner

Burner sizes: 50 to 200

Capacity: 10 to 1000 kW

Uses: cold air, hot air, flat flame, and high-temperature applications

Fuel Types: natural gas, coke oven gas, town gas or liquefied gases as well as biologically produced methane or low calorific value gases upon consultation

Burner length: 300 to 1200 mm

Gas Connection: threaded

Versions Available: burner with integrated ignition lance, housing with internal insulation

ECLIPSE

Thermjet

The ThermJet features the highest flame velocities available in the industry.

Large turndown combined with high excess air. A wide turndown range with high excess air means ThermJet delivers high velocity benefits and efficiencies across its operating range

Dependable ignition. With ThermJet you can light anywhere in the ignition range with no pilot required

The burners are available in 14 sizes with maximum capacities ranging from 150,000 to 20,000,000 Btu/hr

Installation, operation and maintenance are simple and cost effective.

The industry standard for velocity burners, the low NOx ThermJet represents a technological leap forward in every area of design and performance.

Tube Firing Burner

Eclipse low emissions TFB burners are designed to fire radiant and immersion tubes with inputs from 300,000 to 2,000,000 Btu/hr

Low NOx and low CO

Low excess air capability for high efficiency

Low air and gas pressure requirements

High heat transfer at low noise levels

Reliable ignition at a wide range of firing rates

Can be fitted with Eclipse Bayonet-Ultra recuperators for maximum system efficiency

Bayonet Ultra Recuperator

High efficiency plug in recuperators designed to be paired with the Tube Firing Burner for improved fuel usage

They're frequently paired with Tube Firing burners and suitable for use with exhaust streams up to 2100 Degrees Fahrenheit provide fuel savings up to 30%. Conventional recuperators have only one heat transfer tube

Versatility and adaptability are designed into the Bayonet-Ultra

New or retrofit installations rarely require special brickwork, radiant tube or exhaust modifications

Bayonet-Ultra recuperators are available in four sizes to fit radiant tubes with inside diameters from 3" to 8"

A choice of pressure drops makes it easy to match most existing blower systems

Tube lengths can be adjusted to meet exact installation requirements

During installation, multiple-tube furnaces don’t have to be shut down; only the tube being fitted

BrightFire 200

The BrightFire 200 burner provides superior flame and heat transfer adjustability by providing a gas flow adjustment in addition to area adjustment.

Very low NOx

Can be tuned to maximize heat transfer and minimize NOx

Single gas connection for simplified, cost effective application

Compatible with Eclipse mounting bracket and socket plate for easy installation

Compatible with current BrightFire gas and cooling air connections for easy conversion

Nozzle combinations allow firing to be tailored to furnace requirements

Durable construction

Low maintenance

Improved glass quality

Reduced fuel usage due to improved heat transfer into the glass

Single Ended Radiant Tube Burner (SER)

The new, high efficiency recuperator design incorporates a unique dual finned combustor to provide an increased heat transfer surface for greater fuel savings

SER delivers exceptional heat flux and temperature uniformity

SER cuts fuel costs from 35% to 55% over sealed ambient air burners and even more when replacing atmospheric type burners

NOx emissions are reduced by more than 50% over conventional recuperative burners

Self-recuperative design eliminates the need for external recuperators and insulated piping

The insulated mounting flange and exhaust housing improve heat recovery while creating a much cooler working environment

Burners can be installed either vertically or horizontally in nearly any furnace, either gas or electric.

HAUCK

MegaStar

The MegaStar burner supports a wide variety of liquid and gaseous fuels offering flexibility for optimizing fuel costs.

Emissions of NOX, CO and VOCs are minimized with proven and effective technologies.

Available in sizes ranging from a nominal 25 to 150 million Btu/h (7,327 to 43, 960 kW), for applications up to 1500 ºF (815 ºC). Custom lengths are also available for warm-mix applications.

Low motor starting current reduces utility demand charges

Ideal for sand drying applications

Reduction of thermal and mechanical stresses on the motor during starts

Standard and longnose versions available

Simple installation and set-up