HONEYWELL

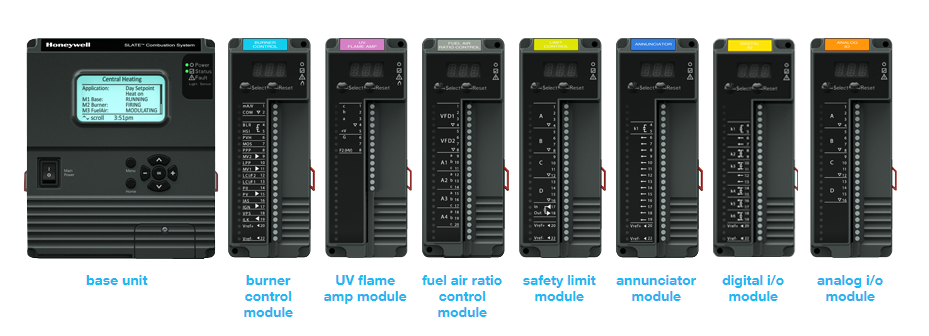

SLATE

The revolutionary integration of configurable safety and programmable logic in a single, modular platform.

SLATE™ streamlines and simplifies the product development process, helping you win in more industries and applications in a matter of weeks – not months or years.

TBC

Compatible to UV, Double rod (separated flame rod and igni-tion rod) and 1 rod (integrated flame rod and ignition rod) flame detection which can be set manually

Integrate 6 kinds of timing choices which can be set manually according to the application requirements

24 hours continuous operation (except UV application)

Life-cycle ≥ 250K times (Note 1)

IP54 protection field or cabinet installation

Multifunctional LED lights and buttons indicate the Flame strength, fault & operation sequence and parameters

Adjustable flame on-off threshold

Remote or on-site reset

Comply with EN298

DBC

Employs a plug-in mounting method

Uses a microprocessor to improve performance

The progress of the sequence can be easily determined by status indicator LEDs

All models have a 4-wire firing rate switching circuit to control an air damper or other auxiliary equipment during startup of the burner.

Safe start check before and during pre-purge

Frontal jack plug (Ø 3.5mm) to read the flame signal with a microampere meter

7800 Series

Ambient temperature -40 to 60°C

Maximum humidity 85 %rh

Flame detector Depends on plug-in amplifier

Modular design with plug-in modules.

Selectable pre-purge time by ST7800A1xxx/U module selection

Accepts all existing Honeywell optical flame detectors and flame rods

kromschroeder

BCU

Modular, all-in-one design

Compact housing

Multi-functional

Easy system integration

High number of switching cycles

IFD

Series 200

Ionization or UV control

Immediate fault lock-out or restart in the event of flame failure, switchable

Safety time on start-up: 10 s

Safety time during operation: 1 s

Mains voltage: 120 V AC, 50/60 Hz

PFU 760 Series

Plug-in function unit for mounting in 19″ module subracks

Flame control by UV, ionization, or by using the furnace chamber temperature

Display of the program status, unit parameters and flame signal; manual mode for burner adjustment and for diagnostic purposes

Programming and diagnostic software BCSoft simplifies logistics management

Air valve control relieves the furnace control

Connection to PROFIBUS-DP via field bus interface PFA 700